Automatic Backwash Disc Filter for Desalination Made From PP Material

Description

Basic Info.

| Differential Pressure Set for Backwash | 0.5-1 Bar |

| Initial Differential Pressure | 0.1 Bar |

| Feed Water Temperature | 4~60°c |

| Core Components | Set of Discs Cartridge |

| Backwash Water Consumption (%) | <0.5% of Total Filtered Water |

| Min. Backwash Pressure | 1.5 Bar |

| Backwash Time | 0~240 Seconds |

| Backwash Mode | Internal Source Backwash (with Filtered Water) |

| Max. Working Pressure | 8 Bar |

| Products Name | High Quality Automatic Backwash Disc Filter |

| Transport Package | Inner Plastic Wrapping, Outside Wooden Cases |

| Trademark | JKmatic |

| Origin | China |

| HS Code | 8421219990 |

| Production Capacity | 10000 |

Product Description

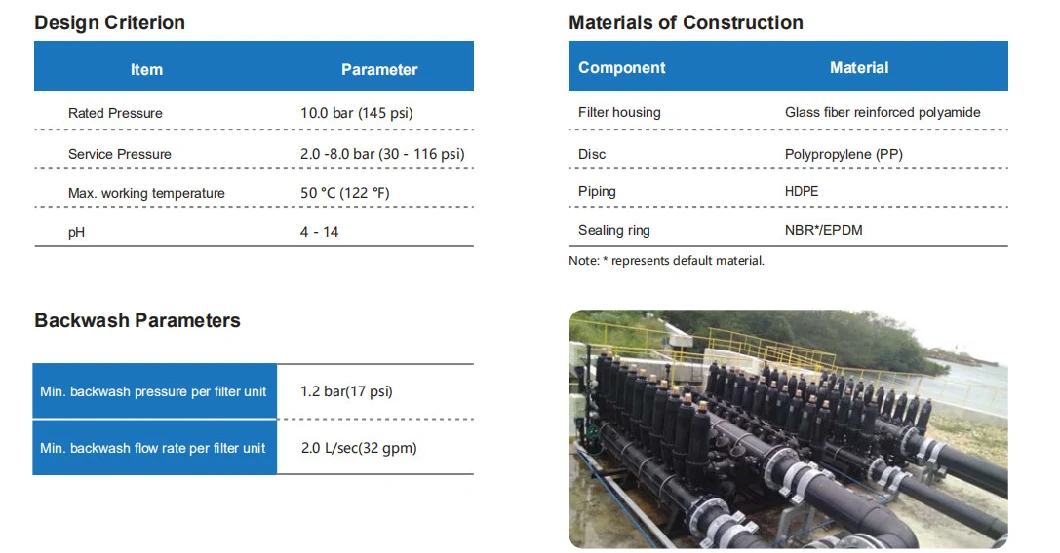

JKmatic Automatic backwash disc filter for desalination made from PA material Specification

| Design Criterion | Material of Construction | ||

| Max. inlet pressure | 8.0 bar (116psi) | Filter Housing | Glass Fiber Reinforced Polyamide |

| Min. inlet pressure | 2.0 bar (30psi) | Disc | Polypropylene (PP) |

| Max. working temperature | 50ºC (122 ºF) | Piping | HDPE/SS304/Carbon Steel with Anti-cossosive Coating |

| pH | 4-14 | Sealing Ring | NBR/EPDM |

| Filtration Grade | 200μm,130μm,100μm,50μm,20μm | ||

| Back wash Parameters | |||

| Min. backwash pressure per filter unit | 1.2 bar (17psi) | ||

Min. backwash flow rate per filter unit | 2.0 L/sec (32gpm) | ||

Main Features

1) Low Pressure Required for Backwash, minimum backwash pressure 1.2 bar (17psi), save energy.

2) No Spring, a patent technology and no Metal Material, no direct contact between water and metal, enhance corrosion resistance feature and lack energy required for backwash.

3) Air Intake & Release Technology, which facilitate backwash efficiency and water saving.

4) Air Buoyancy Check Valve Technology, no metal or rubber contact with water, avoid corrosion or aging.

5) Hydrocyclonic Technology.

6) Quick-lock and Sealing Technology, quick and easy maitenance.

7) It is a robust design and fully automatic.

Technical Description

The core technique of JY filter adopts discs filtration principle. Through deeply pressed grooved plastic discs to achieve combination of surface filtration and depth filtration. There are thin grooves on the surface of the discs, the grooves in opposite direction between discs making many crossed points Therefore the crossed points form many chamber and irregular channels blocking suspendid particles, up to 85%.

When there are many inpurities accumulated in the grooves between discs, inlet and outlet will change opposite direction, compressed discs open automatically and comprssed water injects to discs and the discs rotate quickly, the backwash process completed and the inlet and outlet direction then changed back.

Ready for shippment:

Disc filters are widely used as pre-filters in industrial and commercial areas such as:

- desalination;

- chemical industry;

- food industry;

- textile industry;

- iron and steel industry;

- pharmaceutical industry;

- paper industry;

- other fields of industry.

Also, disc filters are used in the manufacture and operation of:

- power plants;

- industrial and commercial ventilation and air conditioning systems in buildings;

- building materials;

- irrigation systems;

- wastewater treatment;

- municipal water supply;

- in the areas of emergency situations,

- etc.

The Culture of JKmatic:

Benefitting Society,Devotion to build Trust, Hard Work Brings Success,Self Discipline!Our reliable quality and excellent products provide you the space of win-win cooperation, your trust and opinions bring us the prospects of development.

Welcome to contact us!

Our Contact